iMiLAB Radiochemistry

One room to produce various radiopharmaceuticals

iMiLAB Radiochemistry

One room to produce various radiopharmaceuticals

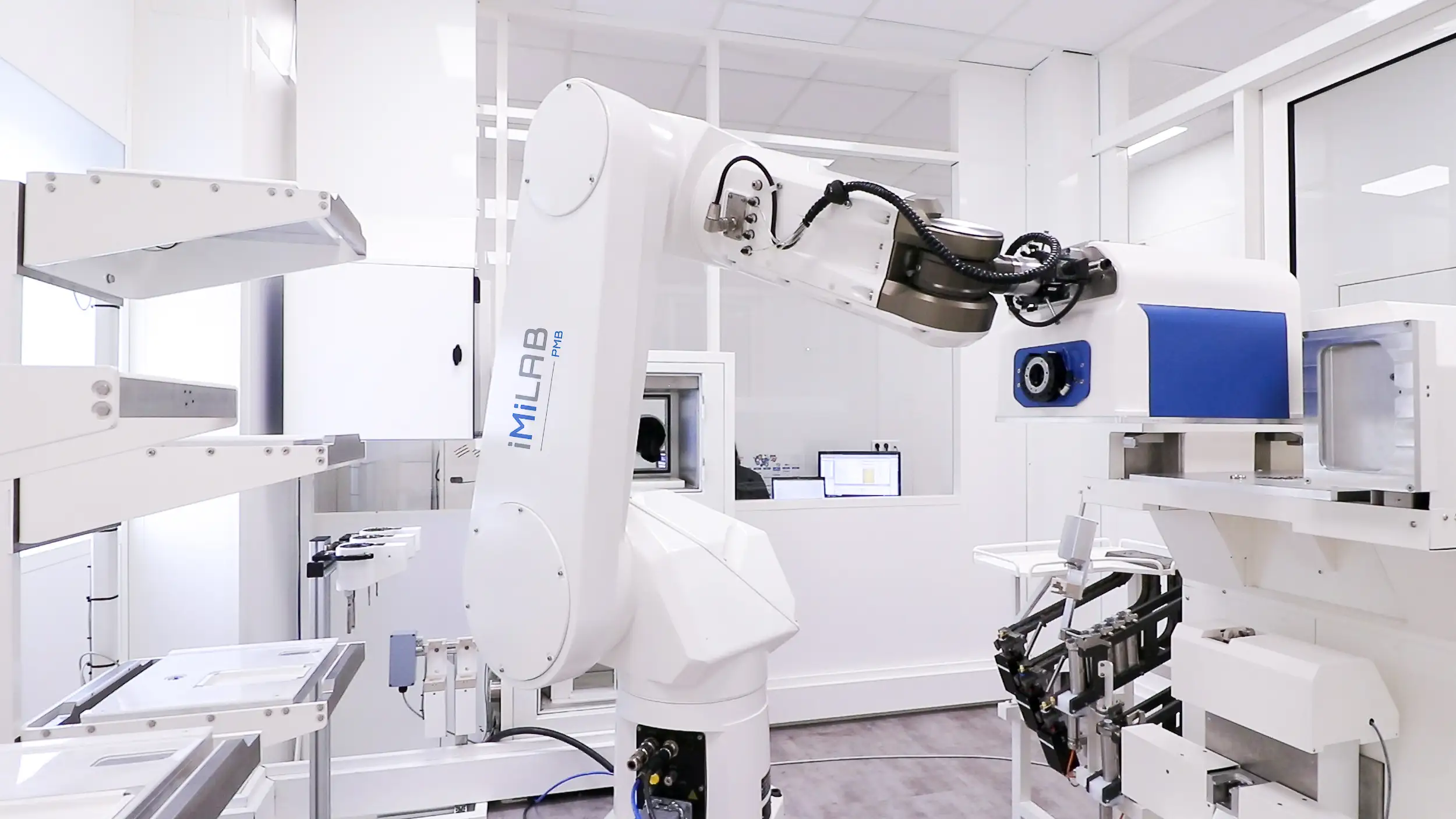

The radiochemistry iMiLAB is compact and self-shielded. Entirely robotized and GMP compliant, the radiochemistry room utilizes microfluidic techniques capable of producing diversified radiopharmaceuticals in an automated synthsizer and cartridges with precursors and solvents. It is capable of synthetizing multiple radiopharmaceuticals on a same-day.

Fully Automated Operation

- Process entirely automated

- Robotized radiochemistry room with a 6-axis robot

- Ready-to-use syringes

iMiLAB is designed for fully automated operation from radiopharmaceutical selection to sterile filter integrity test and syringe-filling. It is equipped with a 6-axis robot, programmed on the intuitive user interface to operate the entire system, after the microfluidic cartridge has been prepared with the adequate precursors and solvents. At the end of the synthesis process, ready-to-use syringes are made available to the radiopharmacist : one for the patient and one for QC, with precise radioactivity measurements.

Innovative & Unique

- Accelerates Particles to 12 MeV: ideal energy for the production of 18F, 11C, 68Ga and 13N

- He-free Superconducting Magnet

- Four External Targets

- Self-shielded targetry

- Lightweight and Compact

- Reliable

As the result of many technological improvements made on the cyclotron OSCAR, iMITRACE is highly innovative and unique. iMiTRACE using a helium-free superconducting and persistent magnet. Due to its particular design, it is a very light cyclotron: it can be installed in a 50 sqm room with only 50-cm-thick walls. The external self-shielded targets and the superconducting magnet allow iMiTRACE to be compact and extremely stable in operation, providing high production yields while not requiring helium cooling.

Moreover, this cyclotron accelerates particles to 12 MeV, the perfect energy for the production of 13N, 11C, 18F and 68Ga which are used for PET imaging. iMiTRACE is able to produce radioisotope batches (up to 3,5 Ci of 18F in 2 hours).

Versatility & Ease-of-Use

- Easy to install

- Automated operation

- Easy to use

- Easy to maintain

Easy to install in both new and existing facilities, iMiTRACE only requires 50-cm-thick walls. Designed for fully automated operation, from target selection and filling, to delivery, iMiTRACE is easy to control. It is equipped with an intuitive and user-friendly interface, designed to give all the necessary information, depending on the operator’s level of expertise and training. Moreover, as the ion source and targets are external, the maintenance of the cyclotron is easier and quicker. This aspect of its architecture allows maintenance operations to be done with less equipment activation, due to the self-shielded targetry, and increased uptime.